With over four decades of excellence in aluminium die casting, OME Verma Industries proudly expands its capabilities into 3D Printing Metal, offering cutting-edge solutions that meet the demands of modern engineering and manufacturing. As a trusted name in precision manufacturing since 1980, we now bring our deep industry expertise to deliver world-class Metal 3D Printing services in India.

Metal 3D Printing, also known as metal additive manufacturing, is a revolutionary process that builds metal parts layer by layer from a digital model. Unlike traditional subtractive methods, 3D Printing enables the production of highly complex geometries, internal structures, and lightweight components that are otherwise difficult or impossible to manufacture.

This technology is transforming industries by offering faster prototyping, reduced material waste, lower tooling costs, and shorter time-to-market — making it an essential service for forward-thinking companies across automotive, aerospace, medical, and industrial sectors.

At OME Verma Industries, we combine our legacy of manufacturing excellence with state-of-the-art 3D printing technology to deliver superior results. Here’s why we are among the most reliable providers of 3D Printing Metal in India:

Decades of Manufacturing Expertise

With over 40 years of experience in precision component manufacturing, our deep understanding of material behaviour, tolerances, and performance gives us a unique advantage in additive manufacturing.

Advanced Technology

We use high-end metal 3D printers capable of working with a range of materials including aluminium, stainless steel, titanium, and more—delivering accurate, strong, and durable parts.

Custom Solutions for Every Industry

Whether you need functional prototypes, small-batch production, or specialised components, we tailor our 3D Printing service to your exact specifications and application needs.

The shift to additive manufacturing offers a range of advantages over traditional methods:

OME Verma Industries provides 3D Printing services for a wide range of applications, including:

Our ability to produce functional prototypes and end-use components helps businesses stay competitive in rapidly evolving markets.

India is witnessing a rapid adoption of advanced manufacturing technologies, and Metal 3D Printing in India is poised for significant growth. At OME Verma Industries, we are proud to be at the forefront of this transformation. We aim to empower Indian manufacturers, designers, and innovators with access to high-quality metal additive manufacturing solutions.

By combining our rich legacy in aluminium die casting with the flexibility of 3D printing, we are uniquely positioned to serve industries looking for both traditional and modern manufacturing capabilities under one roof.

Just like our die casting division, our 3D Printing service adheres to the highest standards of quality and precision. Every printed part undergoes rigorous inspection and post-processing to ensure it meets mechanical, dimensional, and aesthetic requirements.

We use certified materials and follow strict quality control protocols, ensuring that every component we deliver performs reliably in critical applications.

Contact us today to learn more about our 3D Printing services and how we can support your next project with precision, speed, and reliability.

OME Verma Industries is aimed at developing innovations as well as satisfying each customer. This is because our team understands the unique problems employers go through and thus addresses them by using strategies embraced by our organization. It assures that we deliver quality solutions that will adequately address to the detailed requirements of your task.We established the firm with an understanding of the marked that require our services; the unserved market, as they have not been served before. It can be enhancing the quality of goods or services, the time taken or the resources used or delivery time, our team’s focus is on the accomplishment of your goals and objectives.

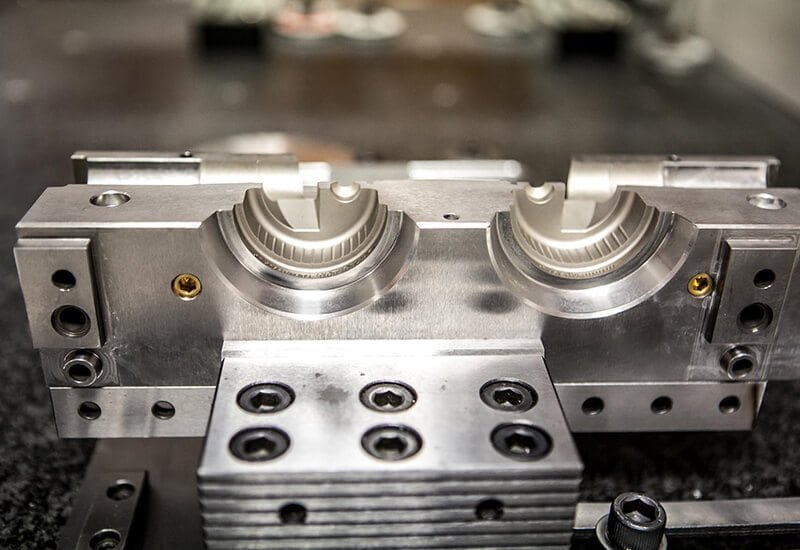

At Ome Verma Industries, we have particularly specialized in the production of High Pressure die cast products as well as design of fine moulds. We use up-to-date design and engineering skills in the creation of our moulds so as to make them be as precise as possible and of high quality as required.

Ome Verma Industries is mainly into mould development that forms the key service strength at our firm. The company was started in early 1980 by Mr. L D Verma, and presently it is efficiently controlled by its director and knowledgeable charioteer of the company Mr. Pradeep Verma, and his son Mr. Vibhhas Verma.

Our skills in mould development have been attained with a skilled and trained workforce, which has put us at vantage for over 35 years.

The 21st-century resources highlighted at the center have unique working stations and qualitative tools. High-precision machines and equipment are used to build moulds and this makes our general performance as well as the quality of the projects excellent. We convey the idea that accuracy is vital when it comes to designing the mould. The complex procedures together with commitment towards work guarantee that each mould we create is of high precision as well as endurance.

We offer a range of services.

The mould of higher standards and precisely made for particular fields or operations. From the mould design that we offer, we guarantee that you get high-quality and durable moulds that provide precision, improving your production process.

Taking time at least once in a while to inspect and maintain your moulds to enhance its functionality. Regular maintenance minimizes interruption and thus increases your productivity. Our experienced personnel offer quality service and repairs for your moulds.

Expertise in creating custom moulds tailored to your specific project needs. We develop unique tooling and prototypes that meet exact specifications, ensuring your products achieve the highest standards.

High-quality automobile specific moulds, built for optimal performance and high durability. Our moulds guarantee that automotive parts are manufactured accurately and durably for high-level usage.

Moulds for energy sector applications, engineered to meet high standards of quality and safety. We provide precision moulds for components used in energy-related industries, ensuring they meet or exceed current standards.

Leaders in the production of precision moulds for mechanical components. Our high standards and advanced technology guarantee the best performance and reliability for your mechanical parts.

At Ome Verma Industries, we prioritize innovation and precision in our mould development process. Our goal is to enhance your business by providing top-quality moulds tailored to your specific needs.

We begin by thoroughly understanding your project requirements and industry standards. Our skilled engineers use advanced CAD/CAM software to design high-precision moulds, ensuring optimal performance and efficiency.

At Ome Verma Industries, we deliver top-tier mould development solutions tailored to meet the diverse needs of various industries. Our expertise in precision engineering ensures that each mould we create is of the highest quality and reliability.

OUR TEAM

OUR TEAM

OME Verma Industries is aimed at developing innovations as well as satisfying each customer. This is because our team understands the unique problems employers go through and thus addresses them by using strategies embraced by our organization. It assures that we deliver quality solutions that will adequately address to the detailed requirements of your task.We established the firm with an understanding of the marked that require our services; the unserved market, as they have not been served before. It can be enhancing the quality of goods or services, the time taken or the resources used or delivery time, our team’s focus is on the accomplishment of your goals and objectives.

Since 1980, OME Verma Industries has been a trusted name in the field of zinc die casting, delivering high-quality, precision components to a wide range of industries. With over four decades of experience, we have established ourselves as a leading zinc die casting manufacturer known for reliability, innovation, and exceptional craftsmanship.

Zinc die casting is a preferred manufacturing process for creating intricate, high-strength metal components with tight tolerances and excellent surface finishes. At OME Verma Industries, we leverage the superior properties of zinc—such as its strength, corrosion resistance, and dimensional stability—to produce components that are both durable and cost-effective.

Our advanced facilities and experienced team enable us to handle complex designs and challenging specifications with ease. From initial design consultation to final production, we ensure that each part meets the highest standards of precision and performance.

Known for their aluminium die casting products and as a seasoned zinc die casting manufacturer, OME Verma Industries stands out for several key reasons:

OME Verma Industries provides zinc die-casting solutions for a wide range of sectors, including:

Each component is manufactured with attention to detail, ensuring durability, functionality, and a premium finish.

We believe in sustainable manufacturing practices. Zinc is a 100% recyclable material, and our processes are designed to minimise waste and environmental impact. As a responsible zinc die casting supplier and manufacturer, we continuously invest in eco-friendly technologies and efficient production methods.

With a legacy built on trust, quality, and innovation, OME Verma Industries is your ideal partner for all die casting product needs like metal 3D printing. Whether you’re developing a new product or improving an existing one, we have the expertise and infrastructure to bring your vision to life.

Have questions or ready to start something great? Reach out to OME Verma Industries today. Our friendly team is here to listen, support, and help bring your ideas to life.

OUR TEAM

OUR TEAM

OME Verma Industries is aimed at developing innovations as well as satisfying each customer. This is because our team understands the unique problems employers go through and thus addresses them by using strategies embraced by our organization. It assures that we deliver quality solutions that will adequately address to the detailed requirements of your task.We established the firm with an understanding of the marked that require our services; the unserved market, as they have not been served before. It can be enhancing the quality of goods or services, the time taken or the resources used or delivery time, our team’s focus is on the accomplishment of your goals and objectives.

OME Verma Industry dedicates itself to Aluminium Die Casting while delivering precise and durable solutions with cost efficiency to various industrial sectors. Our organization operates as one of the top Aluminium Die Casting Manufacturers through leveraging implementation of high-quality die casting materials which satisfy worldwide industrial benchmarks. Our manufacturing capabilities of die casting dies enable us to develop client-specific complex components which attain lightweight features together with high structural strength.

The company operates as a die casting manufacturer through extensive experience to produce customized Aluminium Die Casting Products for automotive aerospace electrical and industrial uses. Our role as an established die casting supplier enables us to deliver support for high-volume production as well as advanced finishing and precision engineering to businesses.

We at OME Verma Industries for the past years have pioneered aluminium die casting, which is the first point of fine quality, precision, and durability. We are one of the most trusted aluminium die casting supplier and manufacturer, with our die casting products fully customized to suit applications in multiple sectors. The companies worldwide prefer us as a die casting supplier because we have expertise in die casting dies manufacturing, and every component which is manufactured meets stringent industry standards.

Advanced die casting manufacturing techniques are used to produce high precision, complex and lightweight components. Our manufacturing capabilities include:

– High-Pressure Die Casting (HPDC) – For large-scale production of automotive and industrial components with tight tolerances and smooth finishes.

– Gravity Die Casting (GDC) – Ensures excellent mechanical properties for heavy-duty applications.

– It Reduces Porosity and Improves Durability for Critical Applications (Vacuum Die Casting).

– Our brand of innovation allows us to offer sure and cost effective solutions to industry requirements.

At OME Verma Industries, we custom manufacture die casting products accredited to integrated production lines to suit every application. Our capabilities include:

– Components with intricate designs that are complex, lightweight.

– Thermal and mechanical properties are superior to any other type of alloys, especially high strength Aluminium alloys.

– Tailor-made solutions for specific industrial requirements.

We are one of the top Aluminium die casting suppliers & manufacturers in India and work with the clients to provide high quality die casting products application specific.

Being a reputed die casting manufacturer follows us quality control process to counter such incidences. Our quality assurance process includes:

– Simulations for automated casting of defect free components.

– CNC machining at a great level of precision finishing.

– Non-destructive testing (NDT) and X-ray inspections for structural integrity.

As a leading aluminium casting manufacturer with commitment to excellence, we have strong reputation in the market supplying high performance die casting products to global markets.

Being one of the leading aluminium and zinc die casting manufacturer in India, we are highly specialized in our precision engineering, cutting edge technology and in providing quality.

OME Verma Industries has been a trusted die casting products manufacturer since 1980, delivering precision-engineered components for a wide range of industries. With over four decades of experience, we specialise in creating tailored solutions that meet your exact specifications, whether for small prototypes or large-scale production. Our advanced manufacturing capabilities, commitment to quality, and customer-first approach make us a preferred partner.

Contact us today to discuss your requirements and discover how our expertise in aluminium die-casting can support your project with reliable, durable, and cost-effective solutions. Let’s build something great together.

OUR TEAM

OUR TEAM

OME Verma Industries is aimed at developing innovations as well as satisfying each customer. This is because our team understands the unique problems employers go through and thus addresses them by using strategies embraced by our organization. It assures that we deliver quality solutions that will adequately address to the detailed requirements of your task.We established the firm with an understanding of the marked that require our services; the unserved market, as they have not been served before. It can be enhancing the quality of goods or services, the time taken or the resources used or delivery time, our team’s focus is on the accomplishment of your goals and objectives.