In the world of metal casting, Aluminum Die Casting and Zinc Die Casting stand out as two of the most widely used methods for producing precision parts with complex geometries. Each method has its unique advantages and limitations, making it crucial for manufacturers and designers to understand the core differences when selecting the right material and process for their application.

This article explores the pros, cons, and key differences between aluminum and zinc die casting, helping you make an informed choice for your manufacturing needs.

Aluminum Die Casting is ideal for applications requiring lightweight and high-performance components. Aluminum alloys such as A380 are frequently used for their excellent strength-to-weight ratio.

Zinc Die Casting is preferred for components that require high precision, intricate detail, and strength at thinner walls. Zinc alloys like Zamak 3 and Zamak 5 are commonly used in consumer electronics, automotive interiors, and industrial equipment.

The selection between Zinc Die Casting and Aluminum Die Casting largely depends on the specific application requirements:

For high-quality Zinc Die Casting and Aluminum Die Casting solutions, partnering with an experienced manufacturer ensures the best results. OME Verma Industries, a leading Aluminium Die Casting Manufacturer in India, delivers precision-engineered parts tailored to your needs with modern technology and quality assurance at every stage.

Aluminium die casting is a technique in manufacturing whereby molten aluminium is injected under great pressure into a steel mould. This produces very sophisticated and premium metal products with outstanding surface finishes. Many different sectors, including consumer goods, electronics, automotive, and aerospace, make extensive use of the method.

With an eye toward the keyword “Die casting manufacturer, die casting supplier, aluminum die casting manufacturers, aluminum casting manufacturers, and aluminum die casting manufacturers in India,” we shall investigate the realm of aluminum die casting manufacturers and suppliers in this article.

Companies specialized in the manufacturing of aluminum die cast parts are known as aluminum die casting manufacturers. These producers have the tools, knowledge, and experience required to create premium parts satisfying their client standards. Working closely with their clients, they grasp their needs and deliver them tailored solutions.

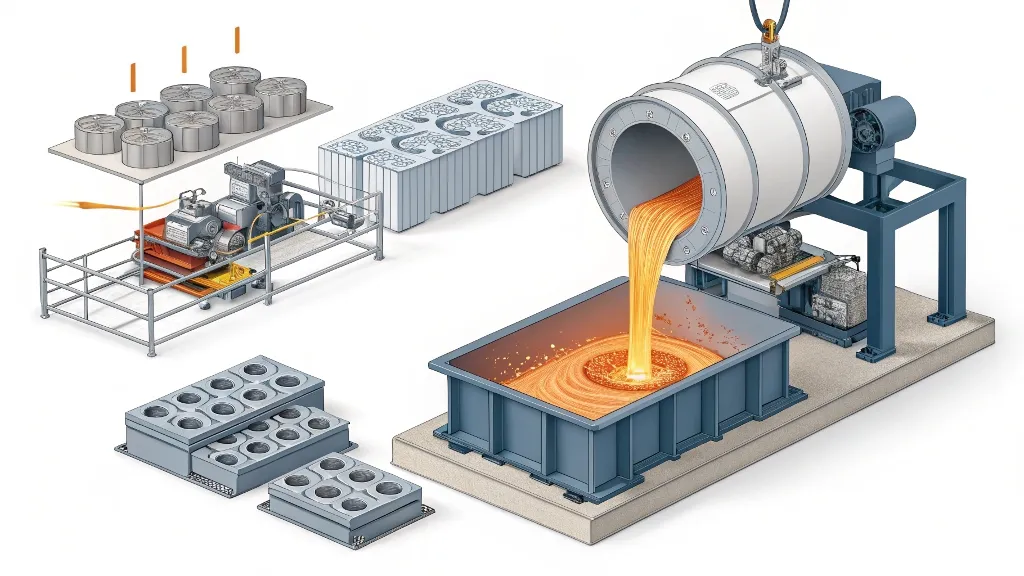

Aluminum die casting calls for multiple steps: mold design; melting and injecting molten aluminum into the mold; cooling and solidification; ejection of the part from the mold; finishing activities including trimming and machining. Manufacturers of aluminum die casting have the tools they need to do these actions quickly and precisely.

Among the best aluminium die casting companies worldwide are Dynacast International (USA), Nemak (Mexico), Ryobi Die Casting Inc. (Japan), and OME Verma Industries (India). These businesses serve a broad spectrum of sectors and are present all around.

Companies who provide raw materials, tools, and services to aluminum die casting producers are known as aluminum die casting suppliers. Since they guarantee producers have access to premium materials and equipment, these vendors are absolutely vital in the manufacturing process.

Aluminum alloy is the main raw good used in aluminum die casting. Different grades of aluminium alloy with diverse qualities including strength, ductility, and corrosion resistance are offered by suppliers. Furthermore necessary for the die casting process are various supplies including lubricants, releasing agents, and coatings.

Apart from raw materials, suppliers also offer tools including die casting machines, molds, and cutting tools. Additionally provided are services including surface finishing, heat treatment, and mold creation and maintenance. Among the leading aluminium die casting providers are Alcoa (USA), Rio Tinto (Australia), and UACJ Corporation (Japan).

Among the top producers of aluminium die cast parts worldwide is India The nation boasts a developed manufacturing industry with superior technology and a trained workforce. Driven by the growing need for lightweight and fuel-efficient automobiles, the Indian aluminum die casting sector is predicted to expand at a CAGR of 8.5% between 2021–2026.

Among India’s leading aluminum die casting companies are Sipra Engineers Pvt. LTD., Sundaram Clayton Ltd., Rockman Industries Ltd., and Endurance Technologies Ltd. Modern facilities and adherence to international quality standards help these businesses provide premium parts for both home and foreign markets.

Popular among manufacturers since aluminum die casting provides many benefits over other manufacturing techniques. Among them Benefits are:

Aluminum die casting presents several difficulties for producers even with its several benefits. Among these difficulties is:

Aluminum die casting companies have overcome obstacles by means of many industry developments. These cover:

Vacuum assisted die casting, or VADC, is the technique whereby the air from the mold is evacuated prior to molten aluminum injection. This enhances the quality of the item by lowering porosity.

High-Pressure Die Casting (HPDC) is a modification of the conventional die casting technique whereby molten aluminum is injected into the mold under greater pressure. Stronger and denser pieces with less porosity follow from this.

Thin-wall die casting is a technique wherein thin-walled objects with wall thicknesses as low as 0.5mm may be produced. This qualifies for uses when weight reduction is absolutely vital.

Additives including strontium and titanium can help the molten aluminium to increase fluidity and lower porosity in die cast products.

One often used manufacturing technique with various benefits over other ones is aluminium die casting. A network of suppliers and manufacturers cooperating to generate premium parts for several sectors supports the sector.

The aluminum die casting business is projected to keep on its expansion path given the growing need for fuel-efficient and light-weight cars. To remain competitive in the market, producers must thus also solve the problems confronting the process and welcome innovations.

Aluminium Die Casting is a commonly used manufacturing process recognised for generating high-precision, durable, and lightweight components. It is extensively utilised in industries including as automotive, aerospace, electronics, and industrial machinery due to its ability to manufacture complicated shapes with outstanding mechanical qualities.

In this article, we will study the numerous aluminium die casting methods, their benefits, and how they contribute to modern manufacturing.

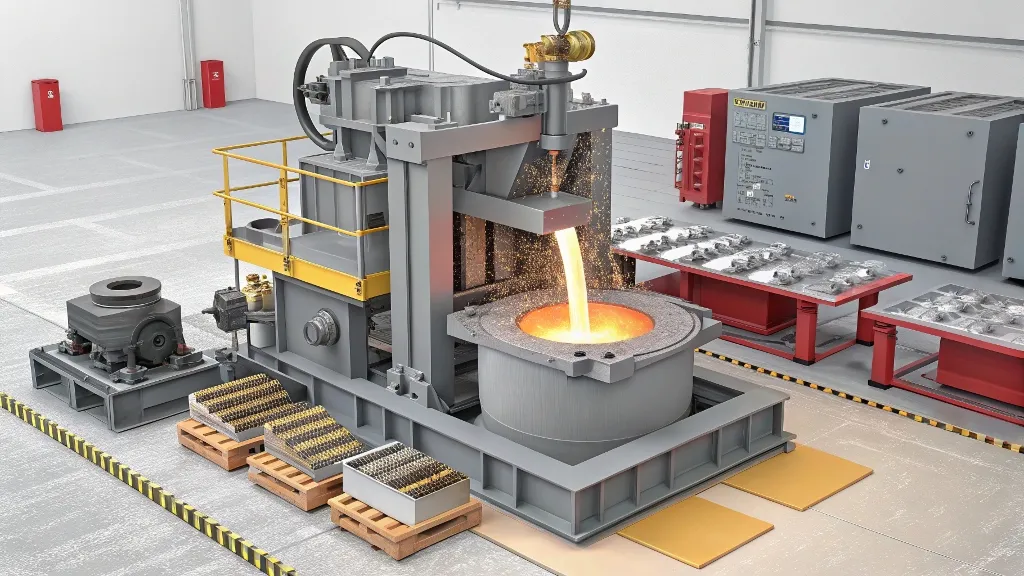

Aluminium die casting is a metal casting method where molten aluminium is pumped into a mold cavity under high pressure. Once cooled and solidified, the part is expelled, producing in a high-strength, lightweight, and dimensionally stable product.

High-pressure die casting is the most prevalent technology for mass manufacture of aluminium components. It involves pressing molten aluminium into a steel mold at high pressure (usually between 1,500 to 25,000 psi).

Advantages of HPDC:

✅ Fast production cycles – Ideal for large-scale manufacturing.

✅ High precision and surface finish – Reduces post-machining requirements.

✅ Strong and lightweight parts – Perfect for automotive and aerospace industries.

✅ Efficient material usage – Minimizes waste.

Common Applications:

LPDC has two advantages:

✅ Better metal flow control – Reduces porosity and defects.

✅ Stronger mechanical properties – Ideal for structural components.

✅ High-quality surface finish – Reduces finishing costs.

Gravity Die Casting (GDC) fills the mould using gravity rather than pressure. Either manually or via a ladle, the molten aluminium is poured into a permanent steel or iron mould.

Advantages of GDC:

✅ Lower tooling costs – Cost-effective for medium production volumes

✅ Better mechanical strength – Ideal for heavy-duty applications

✅ Thicker wall sections possible – Suitable for large components

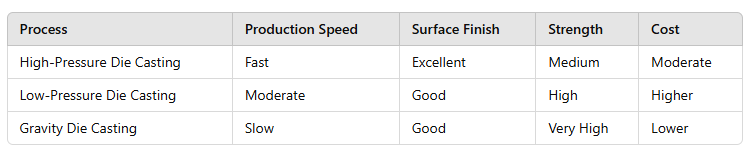

Process choice will rely on elements including production volume, cost, strength requirements, and surface finish considerations. Here is a little analogy:

Ideal for sectors needing strength with less weight, lightweight and strong; cost-effective; lower material waste and short production cycles.

Perfect thermal and electrical conductivity makes perfect for electronic uses; also, corrosion-resistant guarantees long-lasting performance.

Aluminium die casting is an essential manufacturing process that provides precision, durability, and cost efficiency for various industries. Whether you need mass production (HPDC), structural strength (LPDC), or flexibility (GDC), each process has its unique advantages.

At OME VERMA Industries, we specialize in high-quality Aluminium Die Casting Solutions, ensuring top-tier performance and reliability for your business.

Looking for the best aluminium die casting solutions? Visit www.omeverma.com today!

In the ever-evolving world of manufacturing, aluminium die casting has emerged as a cornerstone technology that continues to shape the modern products we rely on every day. From smartphones and vehicles to home appliances and medical equipment, this precise and efficient manufacturing method plays a crucial role in creating durable, lightweight, and complex components.

But what exactly is aluminium die casting, and why is it so influential in shaping today’s products?

Aluminium die casting is a process that involves injecting molten aluminium into a mold cavity under high pressure. These molds, known as dies, are typically made from hardened tool steel and are capable of producing thousands of identical castings with high dimensional accuracy and excellent surface finishes.

This method allows manufacturers to create complex shapes that would be difficult or impossible to achieve using other fabrication methods. The end result is a part that is strong, corrosion-resistant, and cost-effective—ideal for mass production.

Aluminium is one of the most widely used materials to create die casting products due to its excellent properties. It is lightweight, non-corrosive, and has good thermal and electrical conductivity. More importantly, aluminium can be easily recycled, making it an environmentally friendly choice for sustainable manufacturing.

Its lightweight nature makes it perfect for the automotive and aerospace industries, where reducing weight without compromising strength is crucial for improving fuel efficiency and performance.

Aluminium die casting is used across a wide array of industries. Some key applications include:

Die-cast aluminium parts are found in engines, transmissions, and structural components of vehicles. These parts help reduce vehicle weight and improve fuel efficiency without sacrificing safety or performance.

Die casting is used to manufacture heat sinks, enclosures, and housings for various electronic devices. Aluminium’s thermal conductivity ensures that devices remain cool and perform efficiently.

From kitchen appliances and power tools to lighting fixtures and smartphones, aluminium die casting allows designers to create sleek, durable products with a premium feel.

Precision and hygiene are paramount in the medical field. Die-cast aluminium components are used in diagnostic devices, surgical tools, and imaging equipment, offering strength and cleanliness in critical environments.

With advancements in technology, aluminium die casting is becoming even more efficient and precise. Innovations in simulation software, automation, and material science are driving the industry forward, allowing for even greater design flexibility and shorter production timelines.

As industries push for more sustainable and lightweight solutions, aluminium die casting is expected to play an increasingly important role. The demand for electric vehicles, for instance, is accelerating the need for lightweight aluminium parts to maximize battery performance and vehicle range.

When it comes to aluminium die casting, the quality of the final product depends significantly on the expertise and technology of the manufacturer. For businesses seeking reliable and high-quality aluminium die casting solutions, partnering with a trusted manufacturer is essential.

OME Verma Industries is one of the leading aluminium die casting manufacturers in India, renowned for its commitment to quality, innovation, and customer satisfaction. With state-of-the-art facilities and a highly skilled team, OME Verma Industries delivers precision-engineered components that power the products of tomorrow.

Whether you’re developing cutting-edge electronics, automotive parts, or industrial machinery, OME Verma Industries is your trusted partner for all aluminium die casting needs.

The casting of aluminum dies is a very basic process, and it forms the backbone of most other industries, including the automotive electronics industry and aerospace. Those in search of Aluminium Die Casting in Delhi, or finding genuine Aluminium Die Casting Manufacturing in Delhi, we at OME Verma Industries, are ready to take you through the very basics of this process, and why we must be chosen as your partner due to the best decision you can ever make.

In aluminum die casting, liquid metal is forced into a mold of steel, or die, at very high pressure. Very complicated, highly precise pieces of metal are produced that are essential in those industries that need parts to be solid, lightweight, and resistant to corrosion. The speed of the process makes it an effective way to create many high-quality parts.

Delhi is the busy capital of India and is also an important industrial center. Located strategically, Delhi is also variously well-endowed with infrastructural facilities, which makes it an apt place for the industry of Aluminium Die Casting Manufacturer in Delhi The proximity to major markets, coupled with the easy availability of skilled manpower, makes it an ideal location for manufacturers and suppliers like us, OME Verma Industries.

1) Used to make engine blocks, gearboxes, and parts of transmission.

2) Fuel efficiency is increased as aluminum is a lightweight material.

3) It meets rigorous government guidelines and market expectations.

1) Produces enclosures, heart sinks, and connectors with high thermal facility.

2) Intricate designs that are critical for modern electronic appliances can be performed.

3) The accurate fitting and reliable functioning of the parts.

1) Manufactures lightweight, structurally stiff brackets and housings.

2) Decreases the weight of aircraft, which increases fuel efficiency and performance.

3) Impact resistance and Corrosion resistance properties in extreme environments.

1) Precision instrumentation and equipment parts.

2) The high dimensional accuracy that many medical devices depend on to work is provided for.

Lightweight: The feature of low density extends the usage of aluminium making it ideal for applications in the automotive and aerospace industries.

Durability: The properties of the material like the strength and hardness of aluminum mean that the parts we manufacture can endure almost any environment.

Corrosion Resistance: Aluminium products itself is a member of the impedance to corrosion meaning that our die-cast products will last longer.

Cost-Effective: This, coupled with the effectiveness of aluminum die casting makes it ideal for use in large-scale production since it is cheap.

Aluminum die casting is an essential manufacturing step, that meets the requirements of several industries offering high strength, durability, and reasonable prices for the components. This industry is all established in Delhi due to certain tactics, and we at OME Verma Industries are one of the premier Aluminium Die Casting manufacturers in India.